Xiaomi’s Smart EV Factory: producing cars every 76 seconds

Xiaomi’s Beijing EV Factory: A Smart Manufacturing Masterpiece

Hey everyone! It’s your favorite tech enthusiast from xiaomiforall.com, and today, we’re diving deep into something seriously cool that Xiaomi’s been cooking up. Forget just smartphones and smart homes for a second; Xiaomi is now officially a major player in the electric vehicle (EV) world, and their new factory in Beijing is, frankly, mind-blowing. Located in the heart of the Yizhuang economic-technological development zone, this place is all about pushing the boundaries of smart manufacturing. Think a car rolling off the line every 76 seconds, over 700 robots working their magic, and processes that are 100% automated. It’s a true testament to Chinese innovation in the age of Industry 4.0, and it’s seriously positioning Xiaomi as a global automotive contender.

Inside the High-Tech Hub

This isn’t just any factory, folks. Sprawling across a massive 720,000 square meters, Xiaomi’s facility is more than just assembly lines. It’s a complete ecosystem, boasting a sales center, a delivery hub, and even a test track. Talk about a one-stop shop for EVs! The plan is ambitious: to churn out 300,000 vehicles annually across two phases. Right now, they’re producing the Xiaomi SU7, a slick electric sedan that’s already giving the Tesla Model 3 a serious run for its money. And get this: the upcoming YU7 SUV, launched in June 2025, managed to snag an insane 200,000 orders in just THREE minutes. That’s some serious demand!

With a production rate of 40 cars per hour, this Xiaomi factory is among the fastest globally. How’d they pull it off? By leaning heavily into the automation and cutting-edge tech they’ve perfected in their electronics manufacturing. It’s a brilliant application of their core strengths to a whole new industry.

Automation on Steroids

The real star of the show here is the advanced automation. We’re talking over 700 robots working in perfect harmony, streamlining every single step of the car-making process. From the initial stamping to the final assembly, these robots are performing tasks with an almost uncanny precision.

Precision in Every Step

- Body Shop: Get this: 381 robots are busy installing doors and fine-tuning hinges, hitting an accuracy of ±0.5 mm in less than 30 seconds. That’s some serious precision engineering right there!

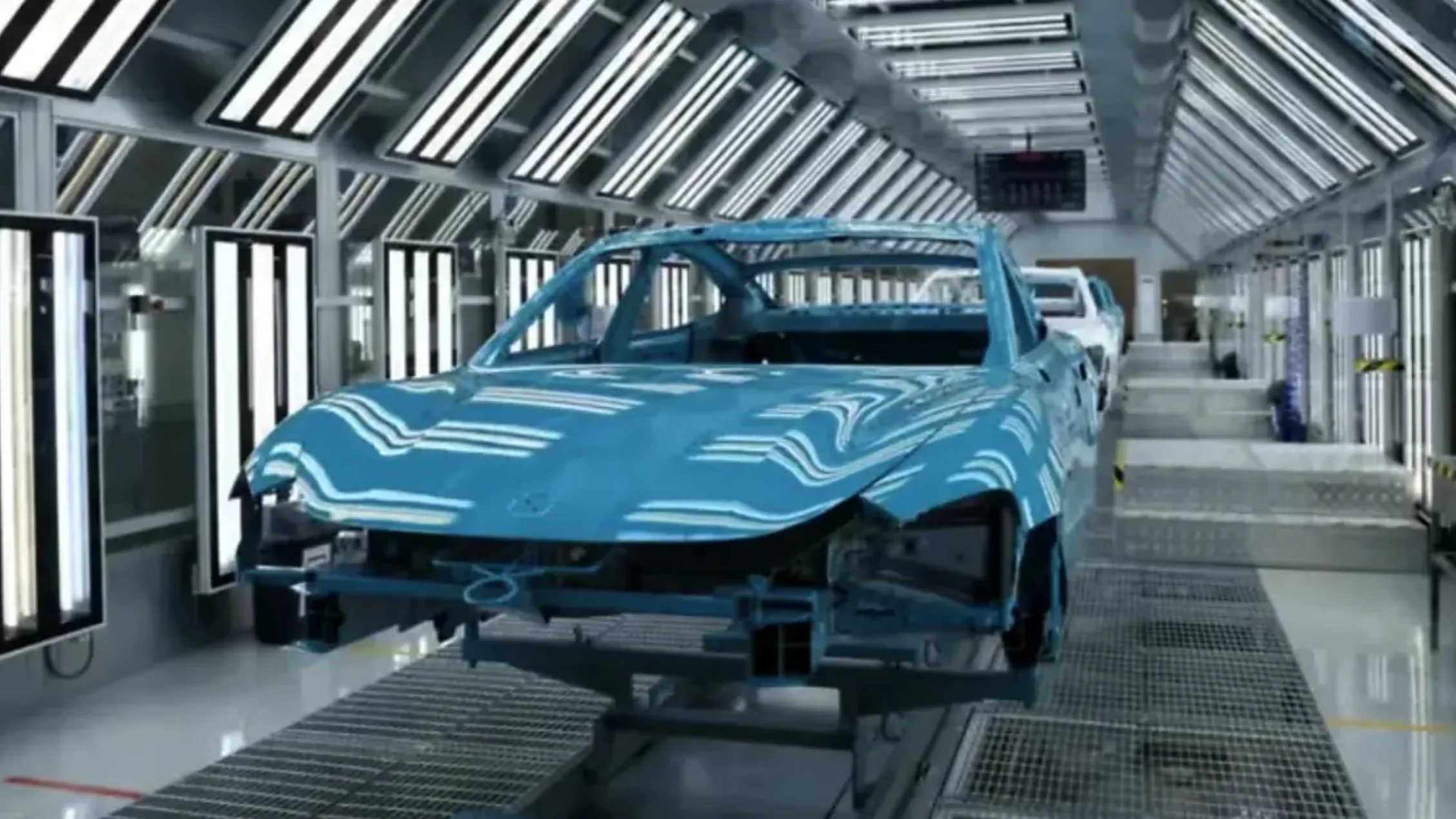

- Paint Shop: To speed things up, they’ve got a rapid color-changing system. This means switching between different paint shades in just 40 minutes, shaving off a significant 25% from delivery times. Pretty neat, huh?

- Battery and Vehicle Assembly: These processes are fully automated, ensuring both efficiency and a near-zero defect rate. Quality control is clearly paramount here.

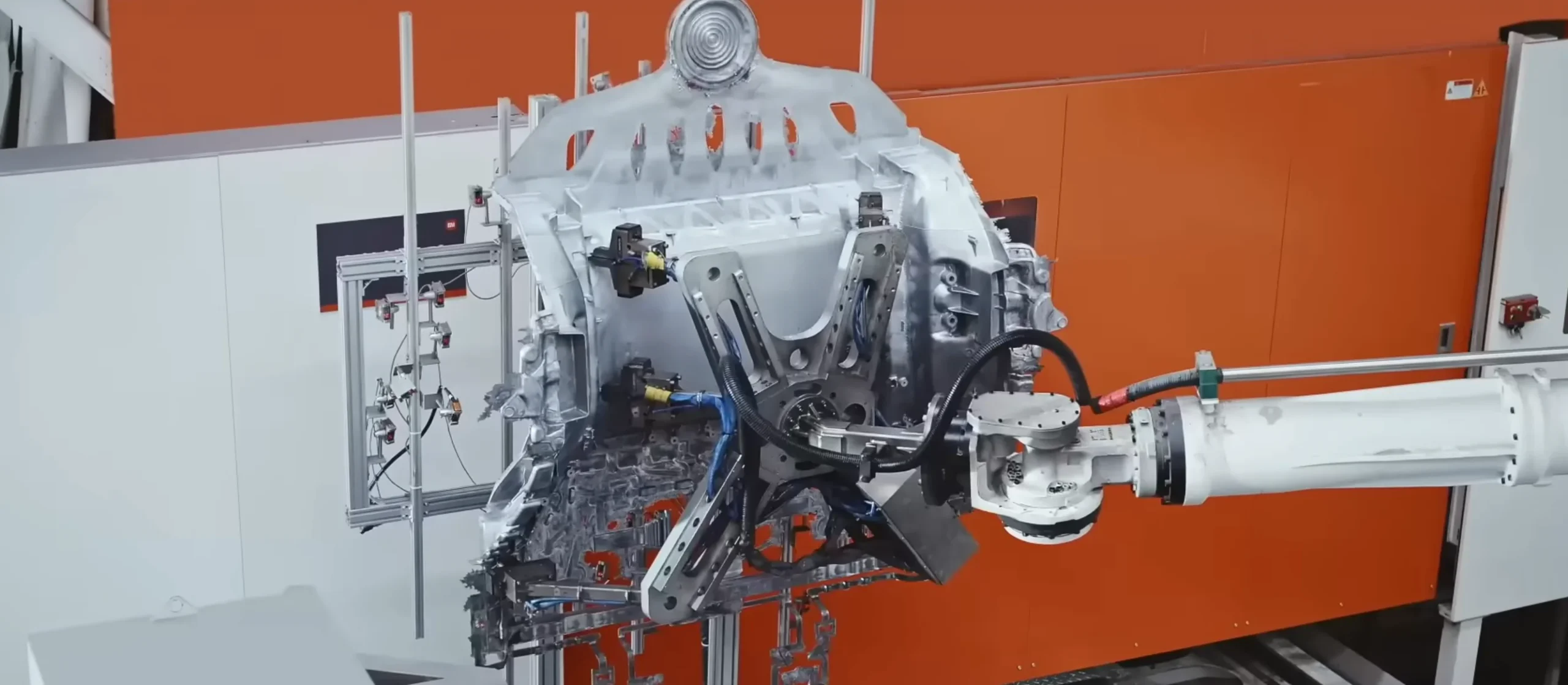

Xiaomi is also adopting Hyper Die-Casting technology, a method made famous by Tesla. This technique allows them to mold massive components, like the entire rear module of the vehicle, from a single piece of aluminum alloy. This not only slashes production time by nearly 50% but also eliminates the need for a whopping 72 separate parts and 840 welding points per unit. Plus, with LiDAR sensors and AI systems on board, they’re achieving near 100% defect detection. That’s a massive win for product quality.

Impact and the Road Ahead (with a few bumps)

Xiaomi’s factory is a prime example of the “new quality productive forces” that China is championing – basically, using tech innovation to drive economic growth. But, as with any groundbreaking venture, there are challenges. The Xiaomi SU7, despite selling over 256,000 units in its first year, has seen some criticism. There have been reports of accidents during test drives, reportedly linked to traction issues. Plus, customers are grumbling about waiting times of up to 30 weeks for certain configurations.

On the global stage, trade tensions are a real concern. With hefty tariffs like the 102.5% slapped on by the US and up to 45.3% by the European Union, Xiaomi’s international expansion could be tricky. This likely means they’ll be focusing heavily on regional markets for now.

What’s Next for Xiaomi in Auto?

Xiaomi isn’t one to rest on its laurels. They’re already building a second factory right next to the current one and have plans for a third within the same complex. The goal is to ramp up production capacity even further. Despite the massive initial investments, the automotive division is projected to hit profitability in the latter half of 2025. With their relentless focus on innovation and scaling up, Xiaomi is seriously challenging established giants like Tesla and BYD, pushing the envelope for smart manufacturing in the automotive sector.

Looking Back and Looking Forward

The Xiaomi EV factory in Beijing is more than just a production line; it’s a powerful statement about the potential of automation and AI in the car industry. Producing a car every 76 seconds isn’t just about speed; it’s about redefining efficiency and signaling Xiaomi’s arrival as a major force in the global EV market. While there are hurdles to clear, both technically and commercially, Xiaomi’s commitment to innovation suggests a future where smart manufacturing plays an even bigger role in how we get around.